CNC Machining

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

Metal parts manufacturing is an industry that uses various metal materials to process parts or components that meet design requirements through cutting, stamping, welding, casting and other processes. Metal parts manufacturing is an important basic industry for the national economy and modernization construction, and it is widely used in fields such as automobile, aviation, shipbuilding, electronics, machinery and so on.

In recent years, with the global economic recovery and the acceleration of the industrialization process, the metal parts manufacturing industry has shown a steady growth trend. According to data, in 2020, China’s metal products output was 165.47 million tons and demand was 133.63 million tons; in 2021, China’s metal products output was 162.08 million tons and demand was 132.30 million tons.

In this process, China as one of the largest metal parts manufacturers and consumers in the world has an important position and competitiveness in the global market. China has a complete industrial chain and supply chain as well as huge market demand and talent reserve. At the same time, China also constantly strengthens technological innovation and quality improvement to adapt to customers’ diversified and personalized needs and increase product-added value and brand influence.

Do you want to know what are excellent China sheet metal parts manufacturers? Do you want to get high-quality and inexpensive sheet metal fabrication parts from them?

If your answer is "yes", please read this list of Top 10 China Sheet Metal Parts Manufacturers in 2022.

Introduction:

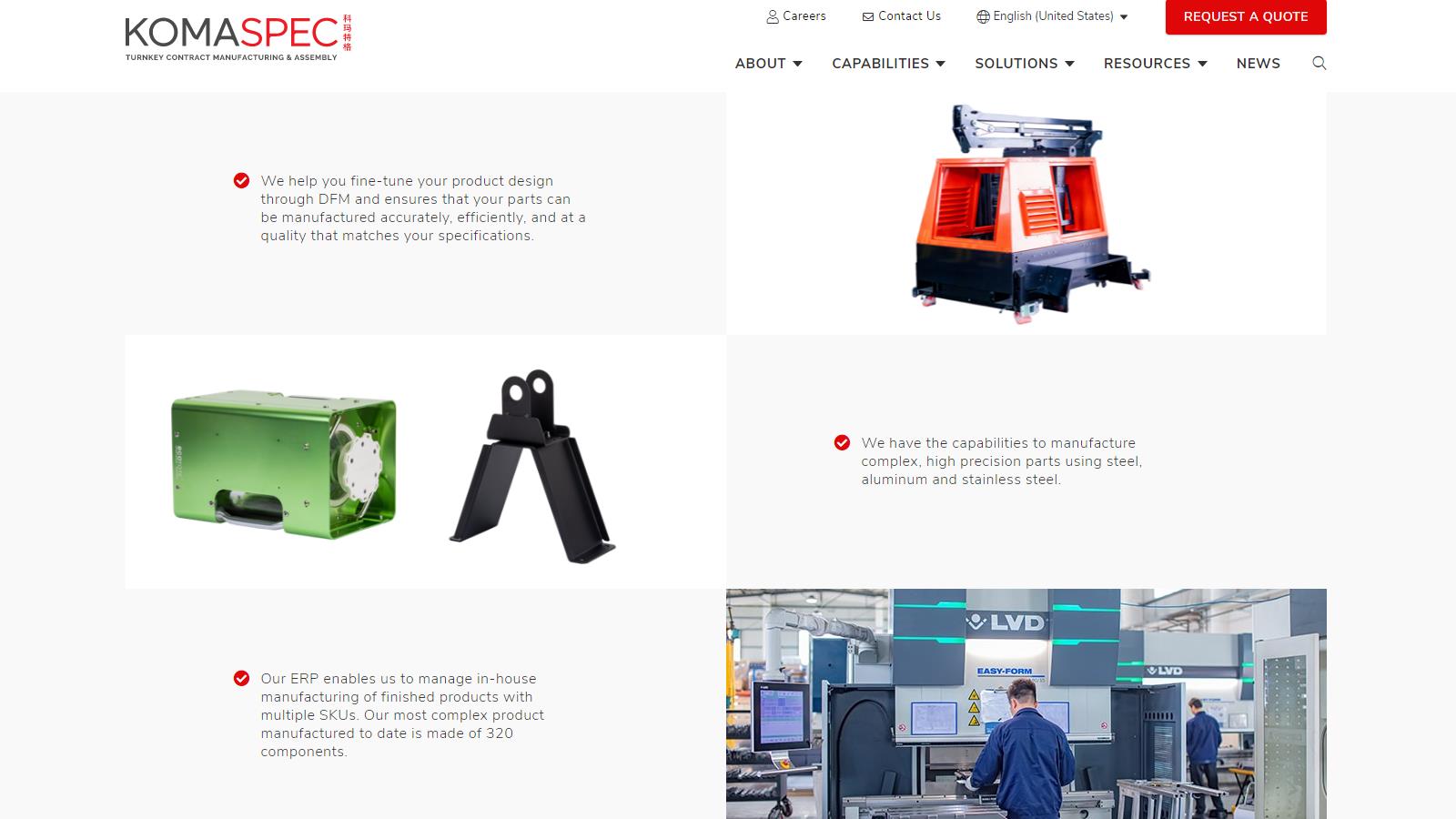

Komaspec is a leading contract manufacturer specializing in the production of metal and plastic parts. It provides a one-stop service from design, prototype, engineering, procurement, production, quality control to logistics. It also has its own online metal-cutting platform that allows customers to quickly order and track metal parts

Compared with other Chinese metal parts manufacturers, Komaspec has the following advantages:

● Scale: Komaspec has two modern factories with a total area of more than 10,000 square meters, fully equipped to meet orders of various sizes and complexities.

● Technology: Komaspec adopts advanced technology and equipment, such as laser cutting machines, CNC bending machines, welding robots, etc., to ensure high-precision and high-efficiency production. It also uses the latest software and systems to manage projects and quality.

● Quality: Komaspec strictly follows the ISO 9001:2015 standard, and has passed many international certifications, such as UL, CE, RoHS, etc. It also implements a comprehensive quality control process, including inspection plans, test reports, traceability, etc.

● Services: Komaspec provides professional and personalized services, including design consultation, engineering support, project management, etc. It also provides customers with flexible and transparent delivery methods, such as FOB or DDP, etc.

● Price: Komaspec uses vertical integration and localized sourcing to reduce costs and provide customers with competitive prices. It also provides customized or standardized solutions according to the different needs of customers.

Introduction:

Redstone is a leading real estate finance and investment company that specializes in multifamily affordable housing. It has the following advantages:

● Scale: Redstone has a large capital base from Prudential Real Estate Investors and a national presence that allows it to handle various projects across the country.

● Technology: Redstone focuses on energy and emerging technologies that have positive impacts on the future. It supports more flexible and decentralized energy systems that empower customers and benefit society.

● Quality: Redstone follows the highest standards of quality and compliance in its financial products and services. It also obtains various international certifications for its energy projects.

● Services: Redstone offers a one-stop service that covers design, engineering, procurement, production, quality control and logistics for its multifamily affordable housing projects. It also provides professional and personalized services for its energy customers.

● Price: Redstone provides competitive prices for its financial products and services by using innovative solutions and efficient processes. It also offers flexible and transparent delivery methods, such as FOB or DDP, etc.

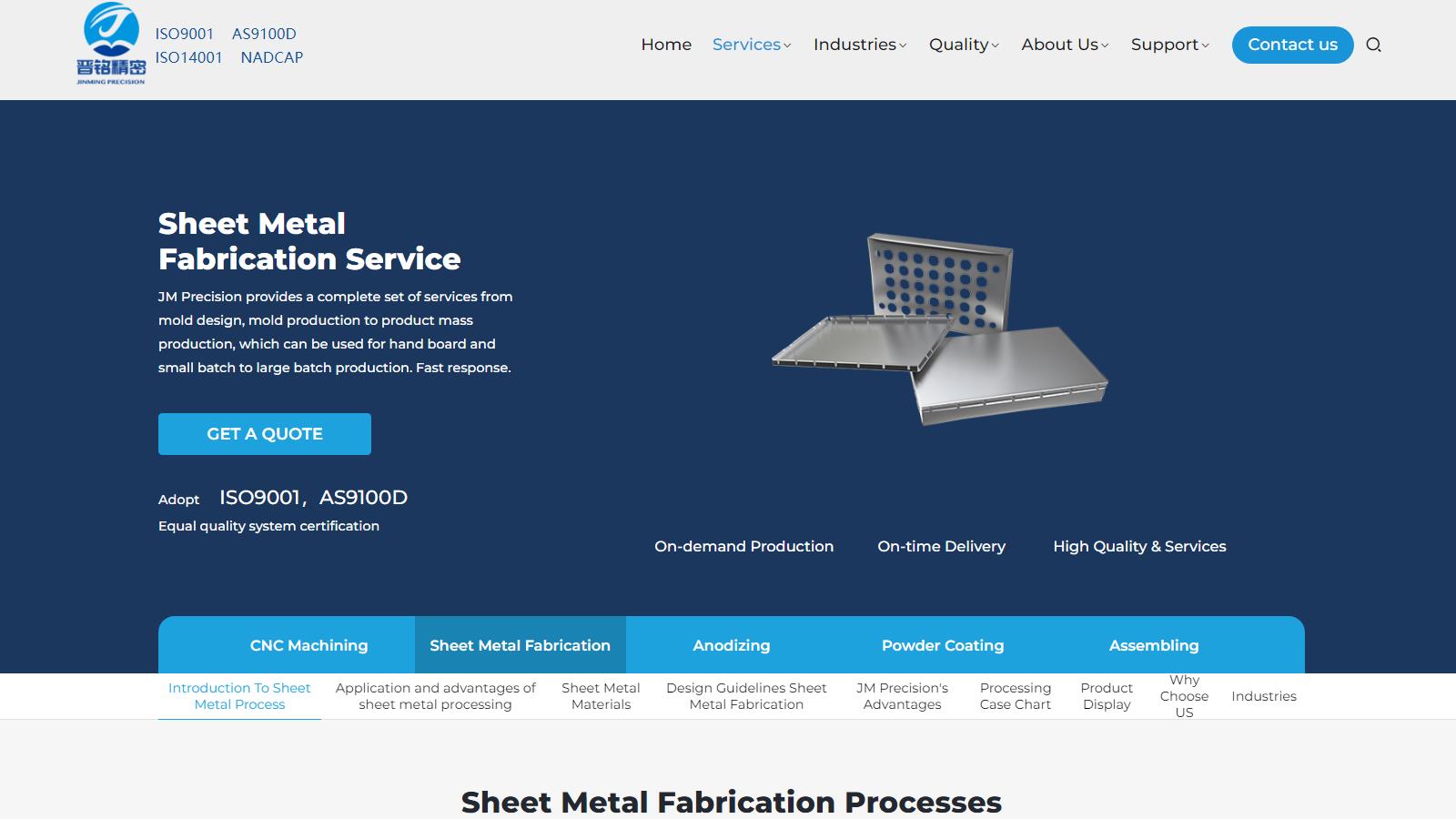

Introduction:

JinMing is a leading contract manufacturer specializing in CNC machining of metal and plastic parts. It provides a one-stop service from design, prototype, engineering, production, quality control to logistics. It also has rich experience in various industries, such as automotive, aerospace, medical, drone, etc. Compared with other Chinese metal parts manufacturers, JinMing has the following advantages:

● Scale: JinMing has a large production capacity that can handle orders of different quantities and specifications. It also has a global network of partners and suppliers that can support its operations and delivery.

● Technology: JinMing uses advanced CNC machines and tools that can produce high-precision and high-quality parts. It also adopts innovative technologies such as 3D printing and laser cutting to meet customer needs.

● Quality: JinMing follows the ISO 9001:2015 standard and has passed many international certifications such as IATF 16949:2016 for automotive industry. It also implements strict quality control measures such as inspection plans, test reports, traceability, etc.

● Services: JinMing provides professional and personalized services such as design consultation, engineering support, project management, etc. It also offers flexible and transparent delivery methods, such as FOB or DDP, etc.

● Price: JinMing provides competitive prices for its CNC machining services by using efficient processes and localized sourcing. It also offers customized or standardized solutions according to the different needs of customers.

Introduction:

KDM is a contract manufacturer specializing in metal and plastic parts. It provides one-stop service from design, prototyping, engineering, procurement, production, quality control to logistics. It also has its own online metal cutting platform, which allows customers to quickly order and track metal parts.

Compared with other Chinese metal parts manufacturers, KDM has the following advantages:

● Scale: KDM has two modern factories with a total area of more than 10,000 square meters and complete equipment, which can meet orders of various sizes and complexities.

● Technology: KDM adopts advanced technology and equipment, such as laser cutting machines, CNC bending machines, welding robots, etc., to ensure high-precision and high-efficiency production. It also uses the latest software and systems to manage projects and quality.

● Quality: KDM strictly follows the ISO 9001:2015 standard, and has passed a number of international certifications, such as UL, CE, RoHS, etc. It also implements a comprehensive quality control process, including inspection plans, test reports, traceability, and more.

● Services: KDM provides professional and personalized services, including design consultation, engineering support, project management, etc. It also provides customers with flexible and transparent delivery methods, such as FOB or DDP, etc.

● Price: KDM uses vertical integration and localized procurement to reduce costs and provide customers with competitive prices. It also provides customized or standardized solutions according to different needs of customers.

Introduction:

Boyan is a company specializing in metal and plastic parts manufacturing solutions. It provides one-stop service from design, prototyping, engineering, procurement, production, quality control to logistics for overseas customers.

Compared with other Chinese metal parts manufacturers, Boyan has the following advantages:

● Scale: Boyan has multiple cooperative factories, capable of handling various types and quantities of orders

● Technology: Boyan uses advanced metal processing equipment, such as laser cutting machines, CNC bending machines, stamping machines, etc., to ensure high-precision and high-efficiency production

● Quality: Boyan strictly follows the ISO 9001:2015 standard, and has passed a number of international certifications, such as UL, CE, RoHS, etc. It also implements a comprehensive quality control process, including inspection plans, test reports, traceability, etc.

● Service: Boyan provides professional and personalized services, including design consultation, engineering support, project management, etc. It also provides customers with flexible and transparent delivery methods, such as FOB or DDP, etc.

● Price: Boyan uses localized procurement and optimized production processes to reduce costs and provide customers with competitive prices.

Introduction:

Dongguan Jiatong(Xunjia) Precision Hardware Products Co., Ltd Was Established in March 2011 and is located in Humen Town, Guangdong Province. The factory has an area of about 8,200 square meters and is a professional precision sheet metal origin manufacturer, providing customers with a full set of the latest automated sheet metal production solutions that integrate Precision Laser Cutting, Fiber Cutting, CNC Robot Bending, Riveting, Welding, Broaching, Drilling, Tapping, Riveting, Shearing, Deep Drawing, CNC Machining, Metal Finishing, Assembling Etc. From blanking to spraying, some processes have been automated.

Introduction:

Sheet metal fabrication is a classification of manufacturing processes that shape a piece of sheet metal into the desired part through material removal and/or material deformation.

Sheet metal is generally considered to be a piece of stock between 0.006 and 0.25 inches thick.

Sheet metal can be cut, bent, and stretched into nearly any shape.

Introduction:

SUPRO is a Chinese company specializing in custom metal parts manufacturing services. It provides global customers with one-stop solutions from design, prototyping, engineering, procurement, production, quality control to logistics.

Compared with other Chinese metal parts manufacturers, SUPRO has the following advantages:

● Scale: SUPRO has many years of experience in metal processing and can handle various types and quantities of orders

● Technology: SUPRO uses advanced metal processing equipment, such as laser cutting machines, CNC bending machines, stamping machines, etc., to ensure high-precision and high-efficiency production

● Quality: SUPRO strictly follows the ISO 9001:2015 standard, and has passed many international certifications, such as UL, CE, RoHS, etc. It also implements a comprehensive quality control process, including inspection plans, test reports, traceability, etc.

● Service: SUPRO provides professional and personalized services, including design consultation, engineering support, project management, etc. It also provides customers with flexible and transparent delivery methods, such as FOB or DDP, etc.

● Price: SUPRO uses localized procurement and optimized production processes to reduce costs and provide customers with competitive prices

Introduction:

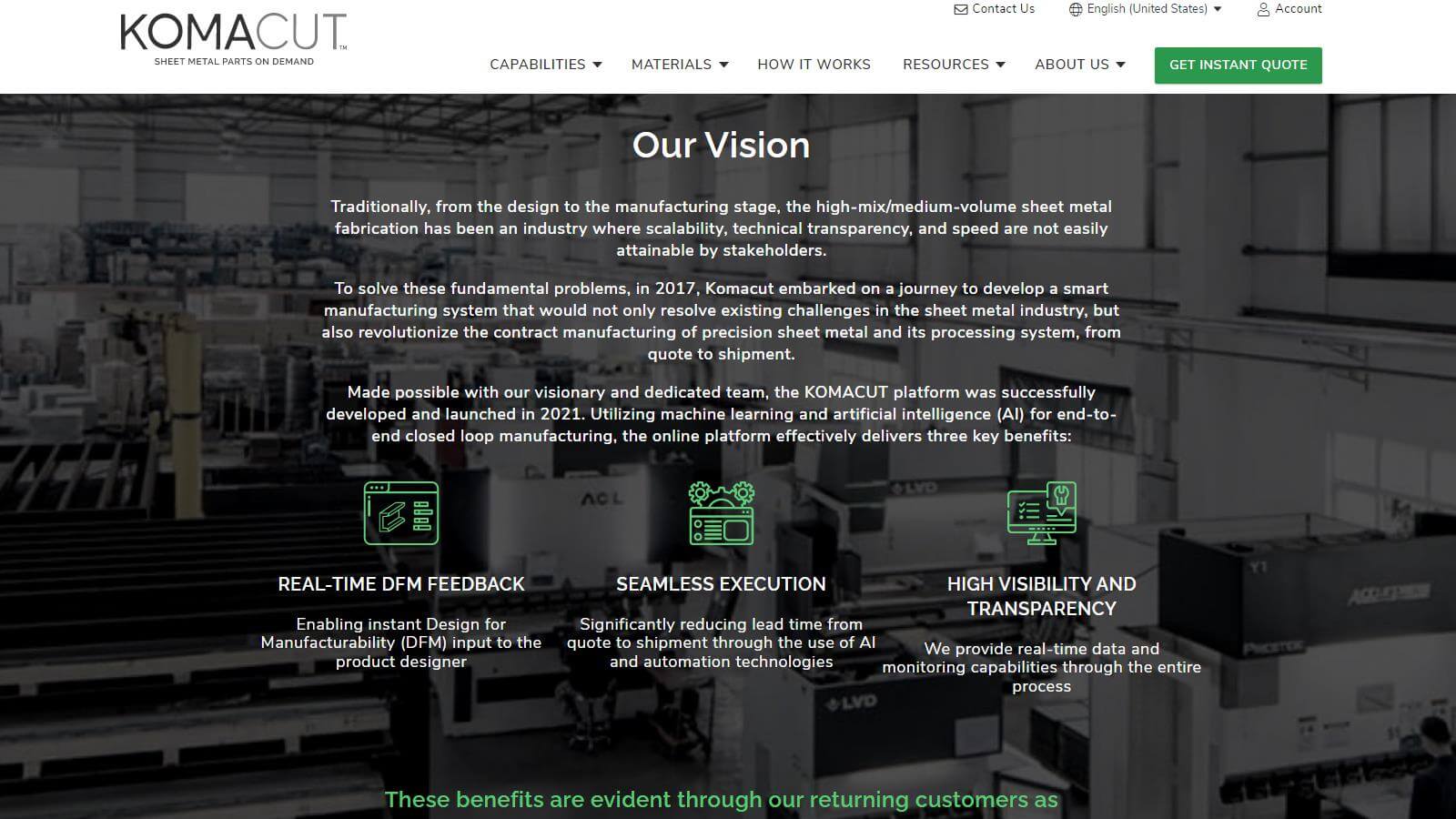

Komacut is a company that provides online ordering services for custom metal parts. It is Komaspec Manufacturing's proprietary platform capable of fulfilling medium to high volume industrial custom production orders.

Compared with other Chinese metal parts manufacturers, Komacut has the following advantages:

● Scale: Komacut has a modern factory of more than 10,000 square meters, equipped with various metal processing equipment, capable of handling orders of various sizes and complexities

● Technology: Komacut uses advanced laser cutting machines, CNC bending machines, welding robots and other equipment to ensure high-precision and high-efficiency production. It also uses the latest software and systems to manage projects and quality

● Quality: Komacut strictly follows the ISO 9001:2015 standard, and has passed many international certifications, such as UL, CE, RoHS, etc. It also implements a comprehensive quality control process, including inspection plans, test reports, traceability, etc.

● Service: Komacut provides a simple and fast online ordering platform, allowing customers to upload 3D drawings, enter some simple parameters, and then get instant design feedback and quotation. Komacut also provides customers with flexible and transparent delivery methods, such as FOB or DDP etc.

● Price: Komacut utilizes the method of ordering directly from the factory to reduce costs and provide customers with competitive prices

Introduction:

Sage Metal Parts is a company specializing in the manufacture and supply of custom metal parts. It has its own factory and reliable partner network, able to meet customers' needs from prototype to mass production.

Compared with other Chinese metal parts manufacturers, Sage Metal Parts has the following advantages:

● Scale: Sage Metal Parts has factories and offices in many countries and regions, able to provide timely services to global customers

● Technology: Sage Metal Parts uses advanced metal forming, casting, stamping and other technologies to be able to produce metal parts in various shapes and sizes. It also uses the latest software and systems to manage projects and quality

● Quality: Sage Metal Parts strictly follows the ISO 9001:2008 standard, and has passed a number of international certifications, such as UL, CE, RoHS, etc. It also implements a comprehensive quality control process, including inspection plans, test reports, traceability wait

● Service: Sage Metal Parts provides professional and personalized services, including design consultation, engineering support, project management, etc. It also provides customers with flexible and transparent delivery methods, such as FOB or DDP, etc.

● Price: Sage Metal Parts uses its own factory and partner network to reduce costs and provide customers with competitive prices

Do you need sheet metal parts for your project? Are you still looking for a reliable sheet metal parts manufacturer in China? We can provide you with customized services to solve your problems. If you need sheet metal parts, please contact us!